The Generator Cooling

Technology 5 – 1.5 MW

Air cooling: simple, clean, easy to maintain

The generator is one of the core elements in the nacelle of any wind turbine. Generating electricity always entails heat losses, causing the copper windings to heat up. To prevent damage to the generator, the heat must be dissipated.

To do so, VENSYS relies on a simple yet efficient air cooling method. The generators of the 1.5 MW platform are cooled using a passive, maintenance-free air circulation system without any moving parts. The ambient air is directed through special cooling channels on the generator housing.

1. ROTOR UNIT | 2. GENERATOR | 3. NACELLE

The Generator Cooling

Technology 5 – 2.5 – 4.x MW

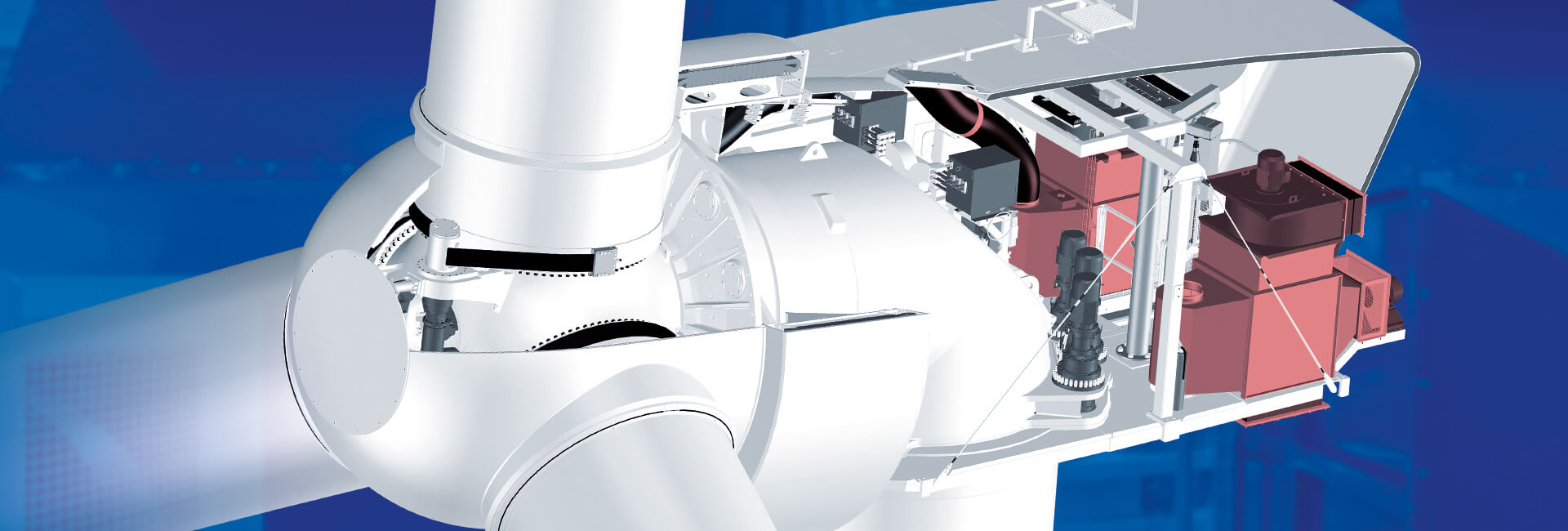

Fully encapsulated and innovatively cooled

The cooling concept has been taken to an even more sophisticated level to suit the needs of the 2.5 – 4.x MW turbines. The result: An active air cooling system fully encapsulated from the external environment featuring an air-to-air heat exchanger. In a closed circuit clean air flows through the stator winding, discharging the losses directly where they arise.

Full encapsulation protects the winding and the interior of the generator from outer influences such as salty and humid air, dust and dirt.

1. GENERATOR 2. NACELLE 3. MOTOR (external cooling circuit) 4. HEAT EXCHANGER 5. MOTOR (internal cooling circuit)

Uncompromisingly customer-friendly

An equally robust and effective system that completely dispenses with the need for consumables such as cooling agents or oils, making VENSYS turbines suitable even for ecologically sensitive areas.