The Idea

Brilliantly simple

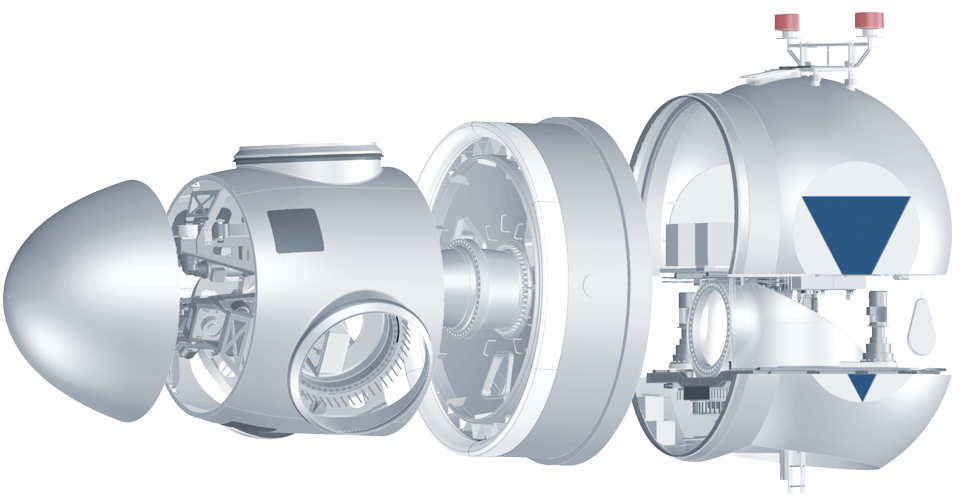

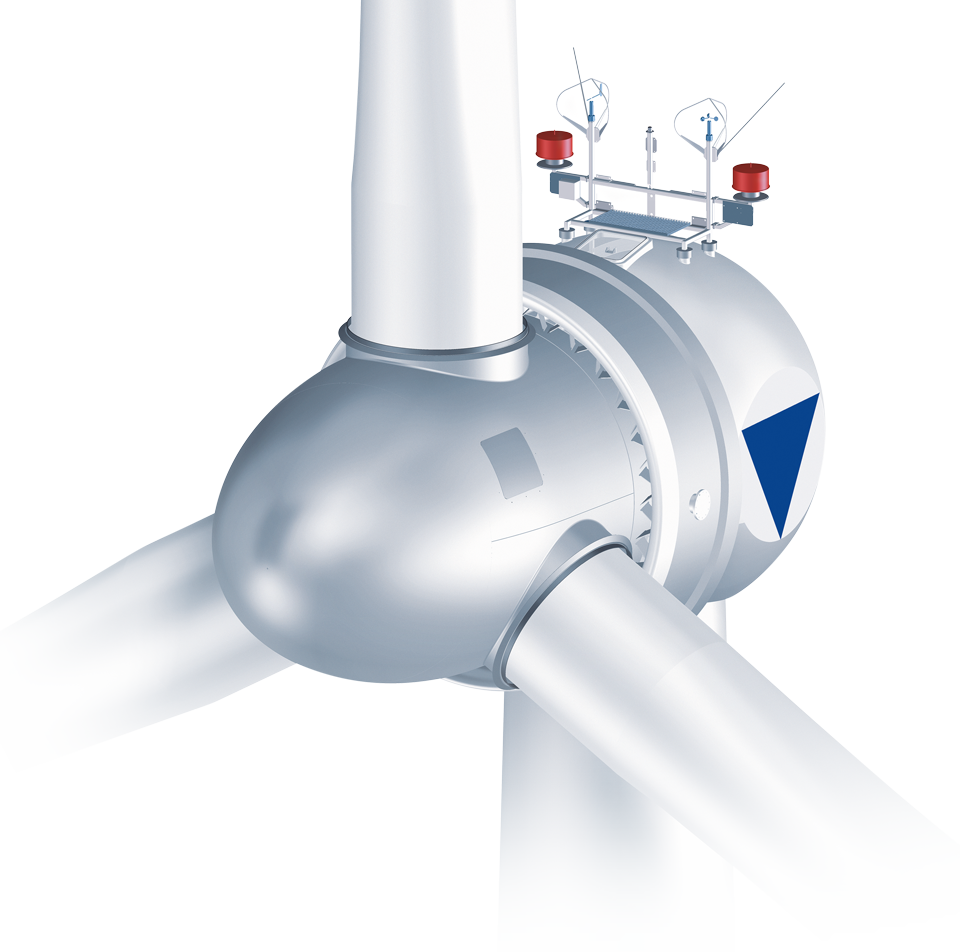

Fewer components, higher wind energy yield, reliable operation

VENSYS Energy AG with its head office in Neunkirchen/Germany develops and manufactures gearless wind turbines.

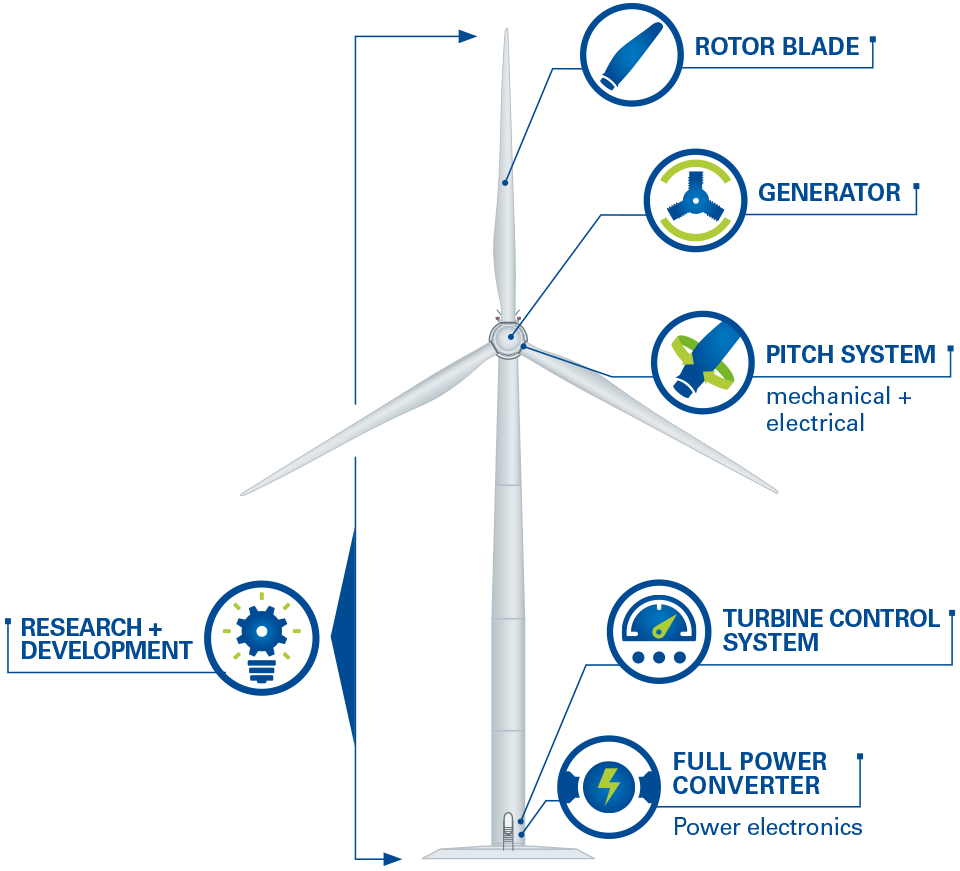

We have made a name for ourselves with high-performance turbines that feature a permanently magnet-excited multi-polar generator, a low-maintenance toothed-belt drive for the blade pitch system, a simple generator cooling and the full-power converter system that allows for a wide range of grid requirements to be met.

The special turbine design relies on a minimum number of high-quality and long-lasting components. High efficiency, low maintenance as well as the compact design and the advantages of systems that are virtually free of wear ensure consistently higher yields.

We deliver the complete range: from the tower base to the tip of the rotor blade

All the core components of VENSYS wind turbines are designed by our experienced engineers and manufactured in different production facilities of the VENSYS Group.

While the full-power converter and the special electrical pitch system are produced at Vensys Elektrotechnik in Diepholz, the multi-polar generator is assembled in Neunkirchen. Production of our rotor blades for different power classes is carried out by E-Blades, our subsidiary in Spain.

It is this interaction of perfectly-coordinated key components paired with our own turbine control system which guarantees reliable engine technology – made by VENSYS.